The threat posed by Houthi militants in Yemen has led to these strategic changes, affecting the transportation of Asian-made components, especially those crucial for electric vehicle (EV) production.

Tesla recently announced the suspension of most car production at its Gigafactory near Berlin, scheduled from January 29 to February 11. The shortage of components, resulting from the re-routing of ships around the Cape of Good Hope, has created disruptions in the supply chain.

In a statement to Reuters, Tesla highlighted the impact of armed conflicts in the Red Sea, causing shifts in transport routes between Europe and Asia. The extended transportation times have led to a significant gap in the supply chains, affecting operations at the Gruenheide-based Gigafactory.

This suspension in production not only showcases the vulnerability of global supply chains but also underscores the interconnectedness of industries across continents. As geopolitical tensions continue to influence logistics, car manufacturers are compelled to adapt to these challenges, leading to delays and disruptions in production schedules.

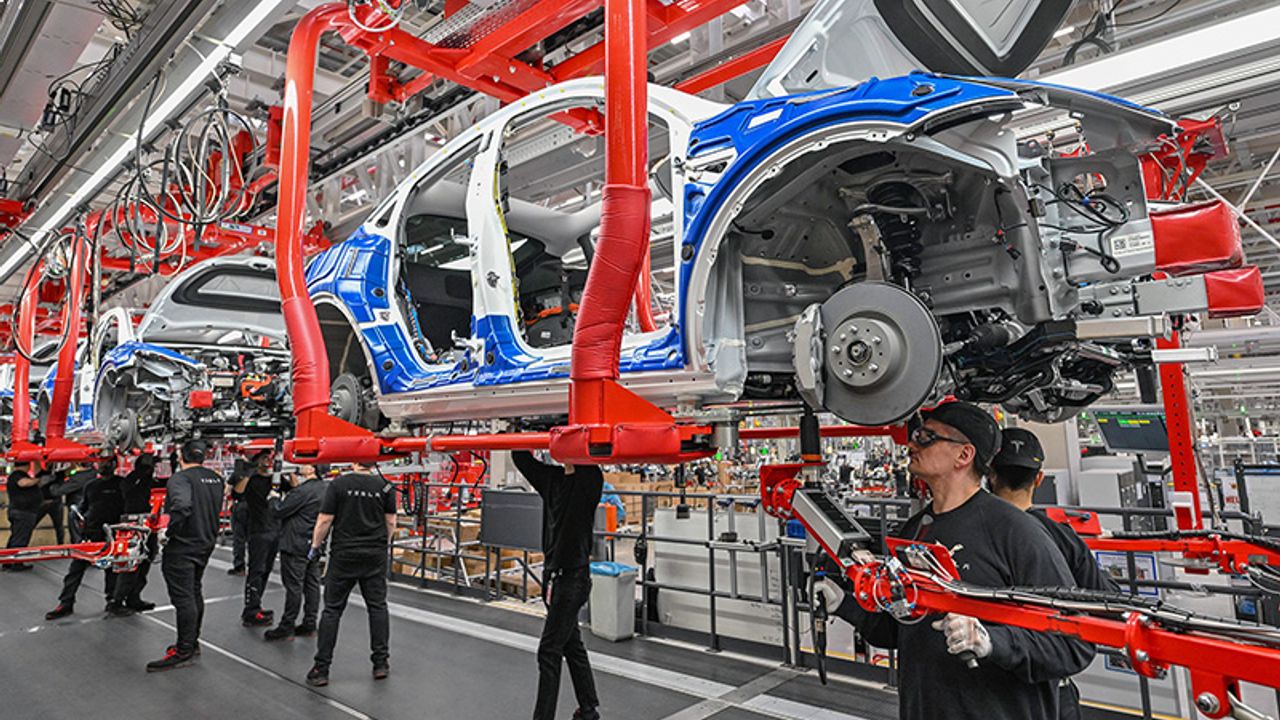

The Berlin-Brandenburg Gigafactory plays a pivotal role in Tesla's European operations, assembling electric vehicles for the regional market.

While specific details about the delayed components were not disclosed, the situation emphasizes the need for resilience and adaptability in the face of unforeseen disruptions in the complex web of global supply networks.